Tungsten Flux

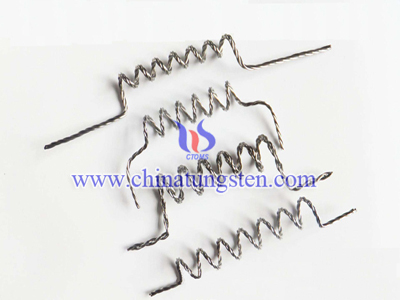

Tungsten flux should be called additive, because the role of additives is not only a flux, as well as fever, adjusting the medium pH, stirring, and the multiple roles of the catalyst, stable combustion, and interference. Tungsten is the hardest molten metal, the melting point is 3380℃, the reason for using it as an additive, because the tungsten is oxidized. Tungsten in the 650℃ in oxygen begins to be oxidized and released a lot of heat, with a high calorific value, and fast response. The oxidation products are acidic oxides of tungsten trioxide, loose volume, it generates the release of CO2 and SO2, will not form a layer of the sample cover.

Sublimation of tungsten trioxide was significantly higher than 900℃.Due to the escape of tungsten trioxide, an increase of the rate of diffusion of carbon and sulfur, carbon and sulfur in the sample fully oxidized. Volatile tungsten trioxide to leave the bath at 700℃~800℃ into the solid phase, covering on the Fe2O3 surviving in the pipeline to prevent the pipeline sulfur adsorption. Tungsten blank value is very low can be used for the determination of low-carbon low-sulfur. General tungsten - tin is used in conjunction with the main role of the additives, tin flux to reduce the impact of lack of tungsten flux.

Non-magnetic material should be added with pure iron.